Solution Provider for Quality Problems

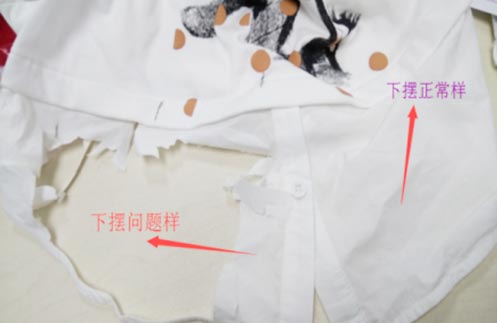

Focused on industry pain points and customer quality issues, GTTC provides professional quality technical consulting services. In the past ten years, GTTC has resolved about 6,000 cases of complaints and consultations from enterprises, shopping malls, and consumers. GTTC has issued more than 800 consultation opinions and quality technical consultation reports. Thanks to the accumulation of technical consulting data for many years, GTTC has established a complete analysis library for quality cases, which covers the issues of implementation standard, pilling, abrasion resistance, sewing damage, broken jean crotch, yellowing, redden due to light-perspiration, penetration of down, penetration of spandex, fibrillation of lyocell fiber, and etc. GTTC accurately identifies quality risks for enterprise products, and provides solutions for corresponding problems.